Our Extrusion Coating and Lamination Technology

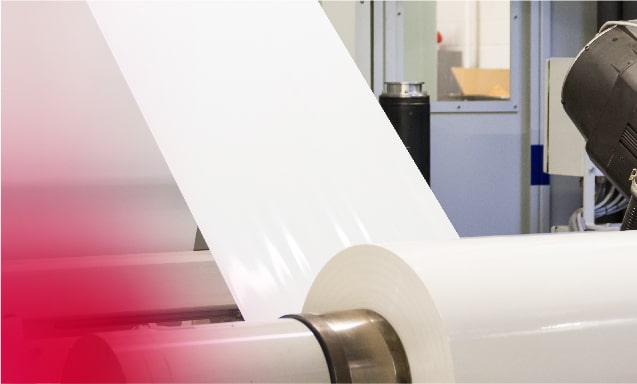

In our high-tech polyethylene extrusion coating lamination production line, all kinds of narrow and wide width paper, aluminum, metallized films, polyester (PET), nonwoven materials are coated and laminated with polyethylene (PE) and other types of copolymers.

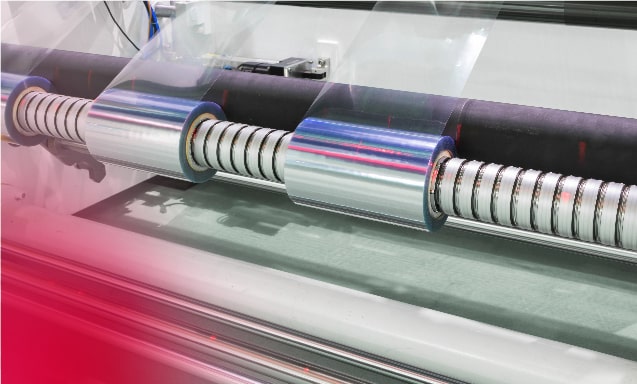

Our extrusion coating lines (2 lines) can process 1650mm and 1350mm widths and a minimum of 8 microns and a maximum of 60 microns of polyethylene coating. Our high-tech extrusion coating & lamination line also enables multi-layered materials to be coated and laminated in the desired weight and thickness, with thickness gauge and automatic T-die.

In order to obtain defect-free and high quality products, our extrusion line and laboratory perform the following applications; base weight measurement, heat seal tests, sealing and peeling force tests, nuclear thickness measurement and automatic thickness control.

Our extruders are capable of processing LDPE, MDPE, PP, EVA and various copolymers and ionomers